Let Star Cutter tooling experts manage your complete tool life cycle from supply to sharpening, helping optimize the life and cost of your tooling. We are experienced in partnering with medium and large companies, providing solutions for controlling perishable tool cost per piece including:

Enhance your cost savings goals with rotary tool reconditioning services

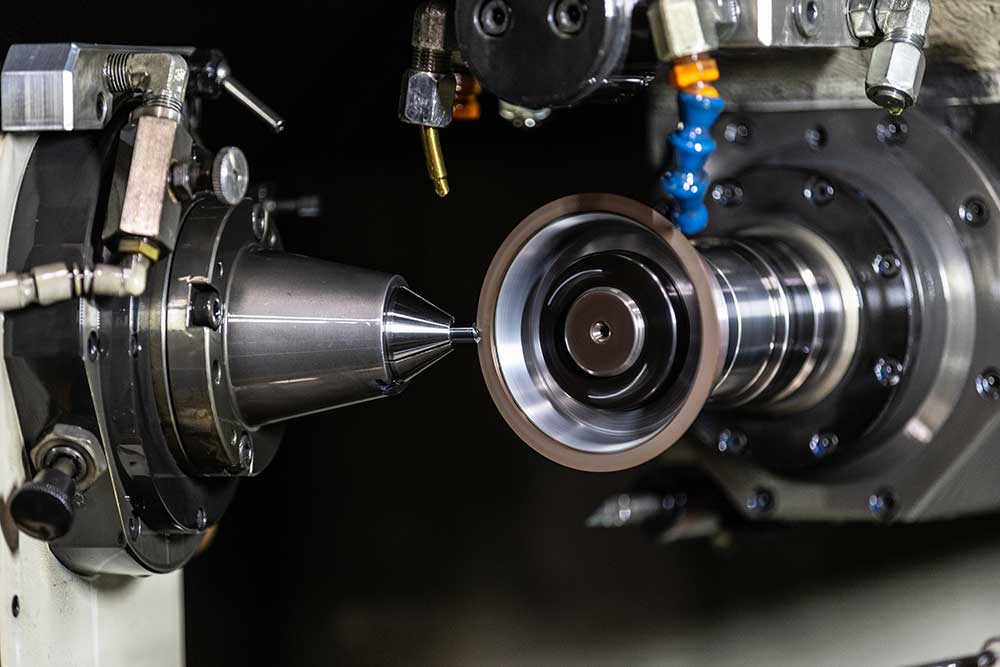

Control your tool costs and keep your tools running efficiently with individualized round tool reconditioning and resharpening support services. We use state-of-the-art technology to restore all types of tools including deep hole drills, special carbide drills and reamers – including cavity port tooling; and fixed pocket PCD tooling to their original sharpened quality, condition, and performance. Advanced recoating services are also available to improve tool performance after Star and other tooling manufacturer’s products

Control costs and run efficiently with resharpening services

Control your tool costs and keep your tools running efficiently with individualized tool resharpening support services from Star SU. From design work to resharpening and recoating, Star SU has the equipment and resources to help you manage your tool room.

We use CNC grinding machines to restore tools to their original sharpened quality, condition and performance, and use advanced coatings from Oerlikon Balzers to improve tool performance after sharpening. Choose your level of involvement – from supplying pure reconditioning services for existing single tools to complete service management with the purchase of the initial product.

Resharpening and recoating services available for:

Star SU tool coatings are done in cooperation with Oerlikon Balzers.

Oerlikon Balzers Tool Coatings utilize the highest degree of technology in all aspects of the coating process to ensure that the maximum quality coatings are deposited on the customer’s tools. Star SU tool coatings are done in cooperation with Oerlikon Balzers.

The cleaning lines, vacuum chambers and inspection equipment are state-of-the-art and unsurpassed by any other provider of PVD coatings. Our own technical expertise and the expertise of Oerlikon Balzers allows Star SU to provide customer support in helping determine the best coating for any application.

Star Cutter Company has developed into a world leader in the cutting tool industry. Each of our six manufacturing facilities specializes in producing a specific type of product or service: solid carbide cutting tools, carbide blanks and preforms, gundrills, gear cutting tools, and 5-axis CNC tool and cutter grinding machines.

Star Cutter Company has developed into a world leader in the cutting tool industry. Each of our six manufacturing facilities specializes in producing a specific type of product or service: solid carbide cutting tools, carbide blanks and preforms, gundrills, gear cutting tools, and 5-axis CNC tool and cutter grinding machines.

23461 Industrial Park Drive

Farmington Hills, MI 48335

Tel. 248-474-8200

Fax. 248-474-9518