Since 1970, Star Cutter has designed and manufactured custom-designed solid carbide drills and reamers for use with CNC production systems, as well as standard and flexible machining systems.

Star’s custom-designed solid carbide drill offering includes single or multiple-diameter tooling, with options of straight or helical flutes with diameters ranging from .1575 (4.00mm) to 4.00″ (101.60mm), as well as an array of carbide grades and advanced coatings options.

Our polished solid carbide drills designed specifically for machining die-cast and extruded aluminum are made from selective wear-resistant carbide grades that include special cutting geometries, bolt hole circles, coolant hole sizes, and advanced coatings for application optimization.

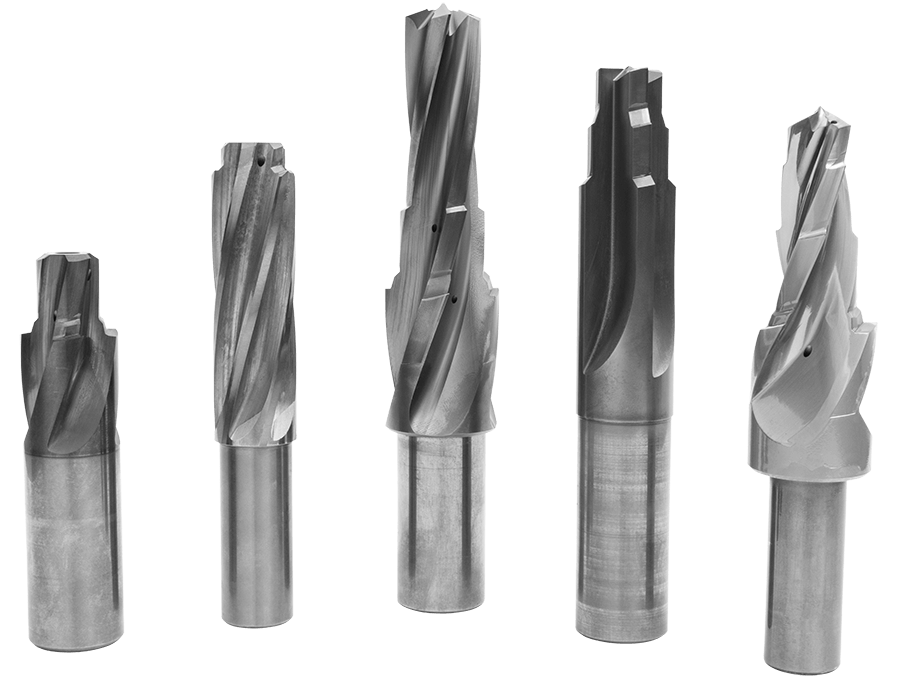

Star Cutter core drills are ideal for machining aluminum, ductile, nodular, and compacted graphite irons (CGI) from solid or cored casting conditions, helping to correct imperfections in the casting for finishing operations. These drills reduce cycle times, provide constancy in the overall life of the product, and machine with reduced harmonics compared to an inserted drill. In addition, solid carbide core drills can be re-sharpened many times, keeping the cost per hole competitive.

Special core drills can also serve as excellent pilot tools in gundrilling operations. The pilot tool can also have a chamfer added, allowing the core drill to combine two tools into one. These are especially helpful for highly interrupted cuts where indexable or insert drills experience performance difficulties.

Star Cutter has perfected a line of hydraulic cavity/porting tools that allow machining from either a solid or cast core casting condition. In many cases, these multi-step tools will allow cavity machining in one pass or shot.

Our latest cavity/porting solutions have replaced traditional high-speed steel, brazed carbide tipped and sub-landed style tools with pressure coolant coated, solid carbide tooling. Our engineering department analyzes the hole diameter sizes and depths of cut to optimize the machining process, typically accomplished with either a single- or two-pass solution.

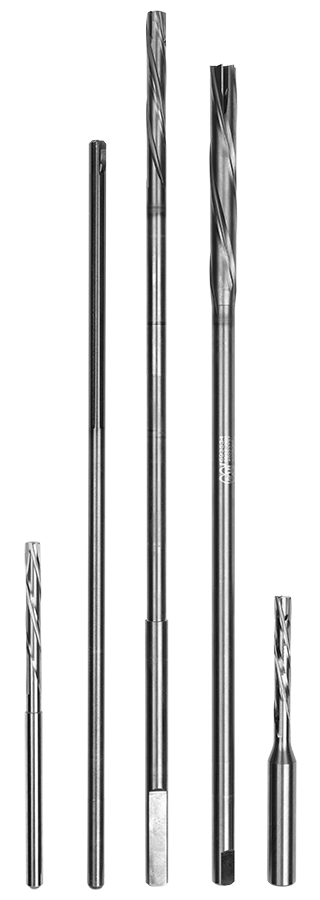

Ideally adapted for enlarging a previous hole condition, Star Cutter pressure coolant reamers are custom-designed using strategic coolant passages, a select number of flutes, and specialized coatings to optimize the tool performance and achieve overall results and improvements.

This unique, patented design combines two tools into one with multiple straight flutes for consistent location and multiple helical flutes to ensure roundness and finish. Our product’s results are within microns in a wide variety of applications, including powdered metal, all irons and more. The SRT offers:

Star Cutter valve guide reamers utilize pressurized coolant to force chips ahead of the tool, producing ultrasmooth, ultraprecise holes in powdered metal and cast iron. Ideally suited for sizing and enlarging previously drilled or cored holes, Star’s valve guide reamers provide higher penetration rates and closer size tolerances.

Our advanced engineering group works hand in hand with valve guide material manufactures R&D centers to optimize our tooling designs to ensure the machinability based on the guide material grade machined. Cutting feeds and speeds are recommended based on the design of the product and the part requirements.

Star Cutter Company has developed into a world leader in the cutting tool industry. Each of our six manufacturing facilities specializes in producing a specific type of product or service: solid carbide cutting tools, carbide blanks and preforms, gundrills, gear cutting tools, and 5-axis CNC tool and cutter grinding machines.

Star Cutter Company has developed into a world leader in the cutting tool industry. Each of our six manufacturing facilities specializes in producing a specific type of product or service: solid carbide cutting tools, carbide blanks and preforms, gundrills, gear cutting tools, and 5-axis CNC tool and cutter grinding machines.

23461 Industrial Park Drive

Farmington Hills, MI 48335

Tel. 248-474-8200

Fax. 248-474-9518