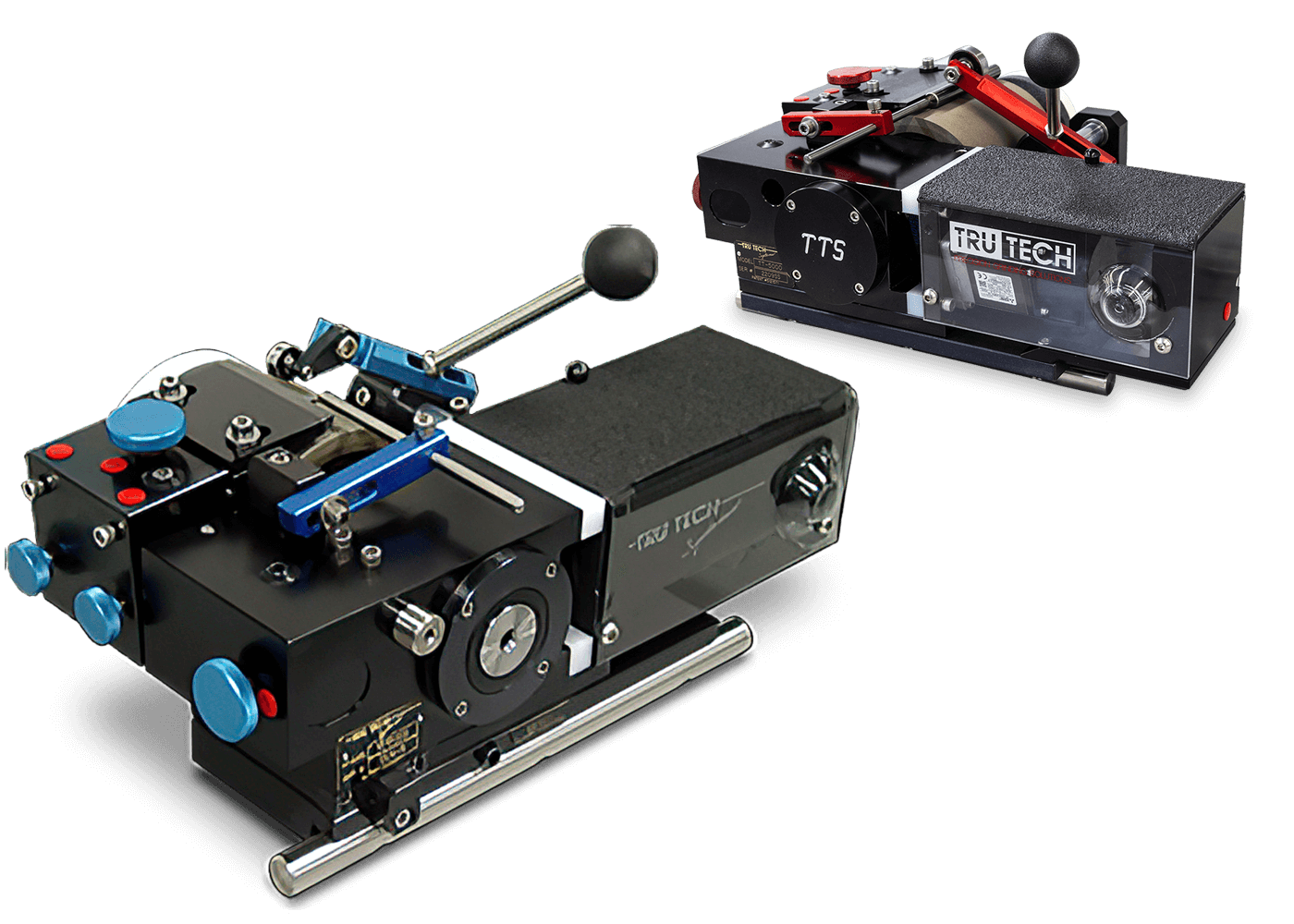

The unique design of the TRU TECH Perimetric Grinding Units removes the need for indicating — a part being ground can be removed from the regulating roller, inspected, and then returned to the regulating roller by hand without any indicating. Part repeatability is within millionths, as well as the concentricity ground within millionths — all without indicating.

The flexibility of these units allows grinding of various shapes and forms all on a wide variety of materials. Diameters as small as .001” and up to 5” can be accommodated. The value-added features allow for reduced set-up times and increased production. The repeatability and consistency of closely held tolerances makes the TRU TECH grinding units an essential item for any high-precision grinding application.

Capability

Features

Options

The PP8000 ultra-precision grinding fixture is both versatile and extremely accurate. With a 3” wide regulating roller, it’s guaranteed to less than 0.000030” (< 1 micron) run-out. This grinding unit is an ideal solution for round tooling and cutting tool blanks where concentricity and roundness are critical.

Capability

Features

Options

Star Cutter Company has developed into a world leader in the cutting tool industry. Each of our six manufacturing facilities specializes in producing a specific type of product or service: solid carbide cutting tools, carbide blanks and preforms, gundrills, gear cutting tools, and 5-axis CNC tool and cutter grinding machines.

Star Cutter Company has developed into a world leader in the cutting tool industry. Each of our six manufacturing facilities specializes in producing a specific type of product or service: solid carbide cutting tools, carbide blanks and preforms, gundrills, gear cutting tools, and 5-axis CNC tool and cutter grinding machines.

23461 Industrial Park Drive

Farmington Hills, MI 48335

Tel. 248-474-8200

Fax. 248-474-9518