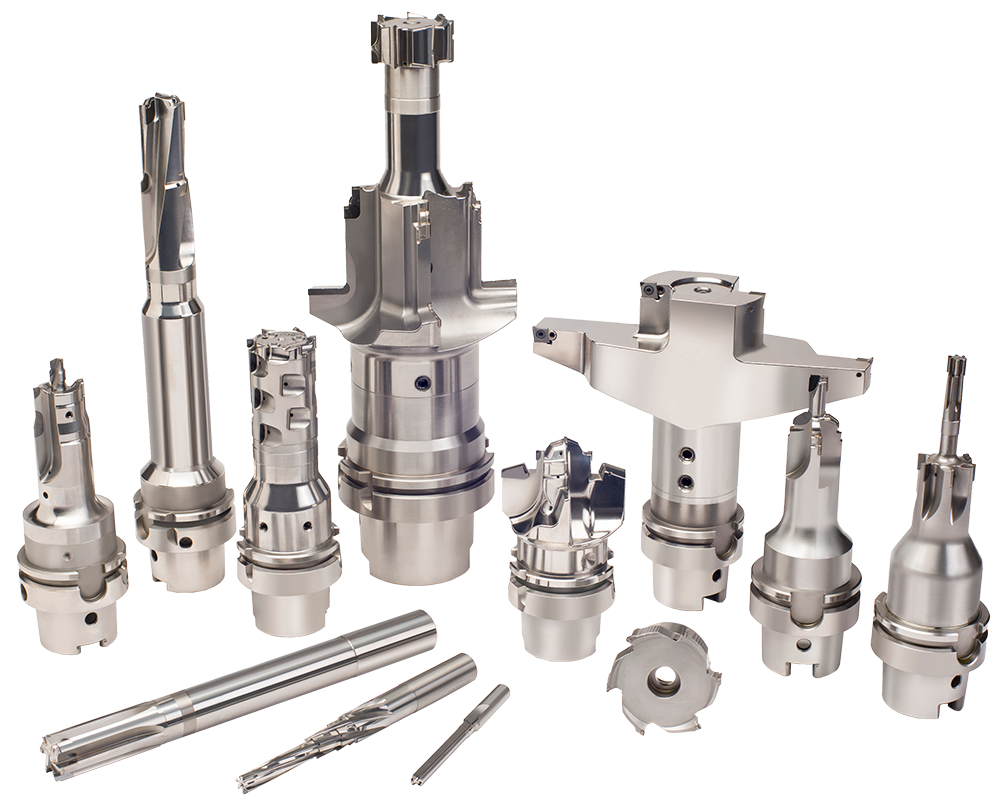

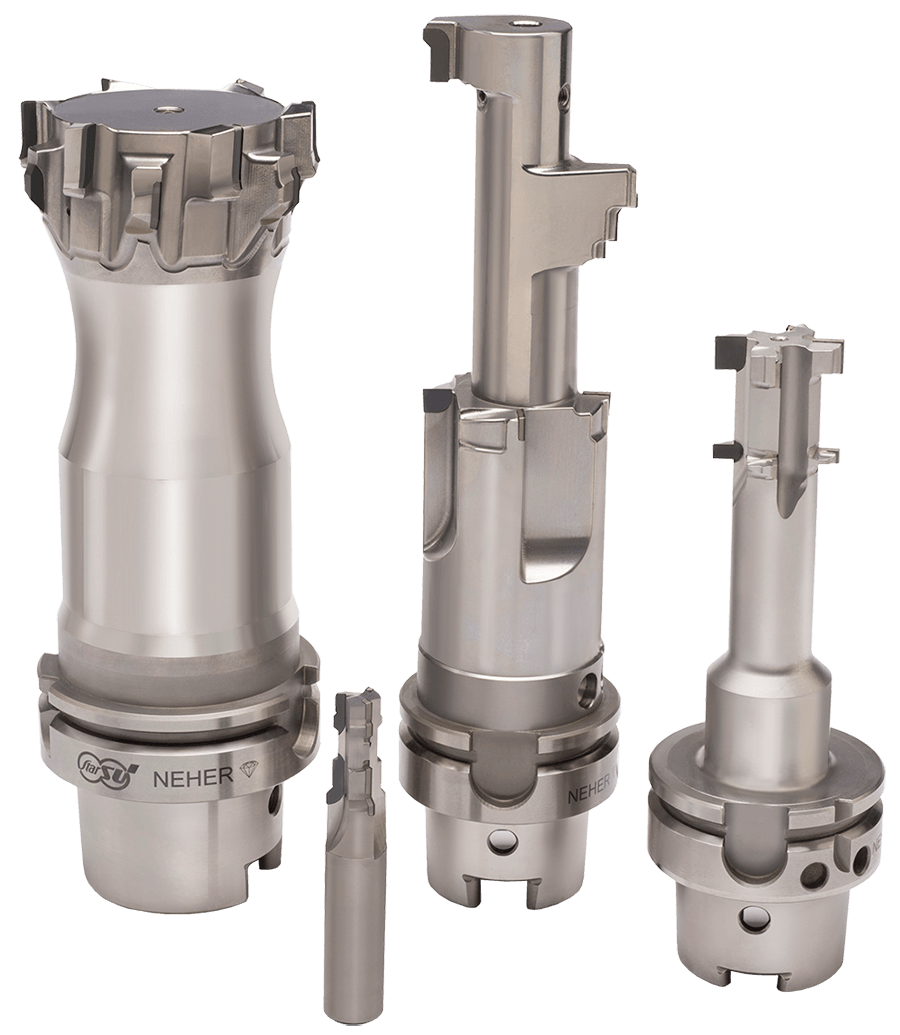

Star Cutter Company, in alliance with our strategic partner Neher Group, produces a line of PCD tools that can be applied to anll types of non-ferrous materials including aluminum, magnesium, copper, brass, wood, graphite, fiber glass, and many more. Tools are offered in both stick tool or monoblock options.

The monoblock tools feature either a one-piece steel or carbide body assembled in the holder, so that the tool is ground true to the holder interface datums. This helps to:

PCD drills from Star/Neher increase part quality with overall consistency, improve surface finish and can reduce tool changes, resulting in an extended tool life.

Our multi-fluted, fixed pocket PCD precision reamer technology has proven to produce excellent part requirements for bore roundness, surface finish and size control. These PCD Precision Reamers are available with multiple step diameters to ensure optimum concentricity and straightness between machined diameters.

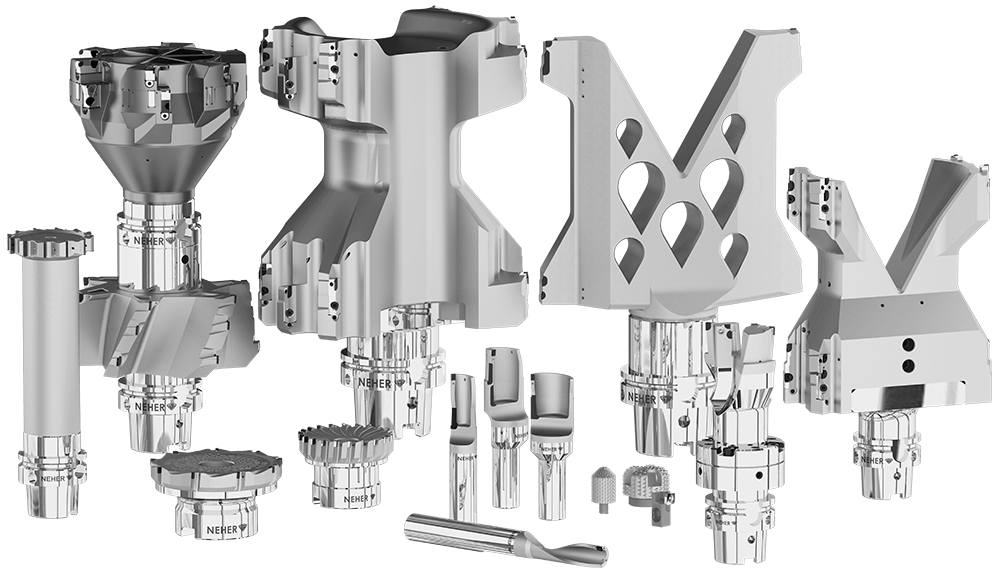

Our custom design PCD milling cutters are available with an adapter or in monoblock styles. The cutters are available with an additive-manufactured body (3D printed) that has been perfected and in production since 2020. The advantages of the 3D printed body include reduction in overall weight of approximately 30%, as well as extremely consistent engineered coolant passages for reliable flow — including MQL applications — that is aligned perfectly to the cutting edge. These advantages have resulted in many cases of tool life improvements of 30% or greater.

Our fixed-pocket PCD Face Milling Cutters are available in standard and increased pitch options. As compared to indexable cartridge cutters, these PCD tools result in improvements to surface finish in normal and interrupted conditions and reductions in cycle time. Using a fixed cutter also does not require tool setups for installing cartridges that in some cases can come loose in the application resulting in scrap and downtime. Another advantage of a fixed PCD Milling Cutter is very consistent cutting lip heights. Special geometries and PCD are used to optimize all silicon conditions, minimizing burrs, and surface finish improvements.

| ø | Standard | Maximum Pitch |

| 40 | Z6 | Z10 |

| 50 | Z6 | Z12 |

| 63 | Z6 | Z14 |

| 80 | Z7 | Z16 |

| 100 | Z9 | Z20 |

| 125 | Z12 | Z22 |

| 160 | Z16 | Z28 |

The special-design PCD pocket mill combines the need for face milling and side wall machining all in one tool. Depending on the application, this tool can be designed to reduce the number of PCD’s needed along the body of the tool to reduce the cost and maintain a defined pitch on the face mill. This tool is also available with a 3D printed body for optimization of the overall process.

Our PCD combination tools are custom-designed for quality improvements and reduction in overall part cycle times. This is accomplished by evaluating combinations of cutting tool features that incorporate drilling, thread milling, spot facing, interpolation and reaming multiple diameters into one tool. Options are available for designing a single tool that can machine multiple part features on one tool. This approach achieves quality improvements and overall cycle reductions by eliminating the number of tools needed to machine a part and tool change reductions.

PCD interpolation tools combine operations into one tool that is capable of milling, interpolating multiple diameters, spot-facing and machining internal forms, reducing cycle times and cost per hole. PCD interpolation tools offer users the ability to:

Since 2020, Star Cutter Company in alliance with its strategic partner Neher Group offers 3D printed PCD monoblock tool bodies and chip deflectors. These additive-manufactured tools are typically applied to large reamers, interpolating and milling cutters where reducing tool weight can significantly impact spindle wear, helping meet customer requirements while being operator-friendly. Plus, these tools can be created with highly complex details and optimized consistent coolant/MQL hole size and engineered locations, helping improve tool life.

Star Cutter Company has developed into a world leader in the cutting tool industry. Each of our six manufacturing facilities specializes in producing a specific type of product or service: solid carbide cutting tools, carbide blanks and preforms, gundrills, gear cutting tools, and 5-axis CNC tool and cutter grinding machines.

Star Cutter Company has developed into a world leader in the cutting tool industry. Each of our six manufacturing facilities specializes in producing a specific type of product or service: solid carbide cutting tools, carbide blanks and preforms, gundrills, gear cutting tools, and 5-axis CNC tool and cutter grinding machines.

23461 Industrial Park Drive

Farmington Hills, MI 48335

Tel. 248-474-8200

Fax. 248-474-9518