Star Cutter Company manufactures rifle barrel making products including gundrills, push and pull reamers, and rifle buttons to geometrical quality with exceptional finishes. We custom design and build these tools using our guidelines to achieve customer part requirements. We assign a unique tool number to every tool we produce with revision control, ensuring our customers get consistent products and results.

There are various methods in the machining of rifle barrels. Deep hole drilling, using a gundrill, is imperative to these processes. While traditional gundrilling has historically proven to be effective, Star Cutter offers a High Performance (HP) Gundrill which is capable of running up to 3-4 times faster than a standard gundrill.

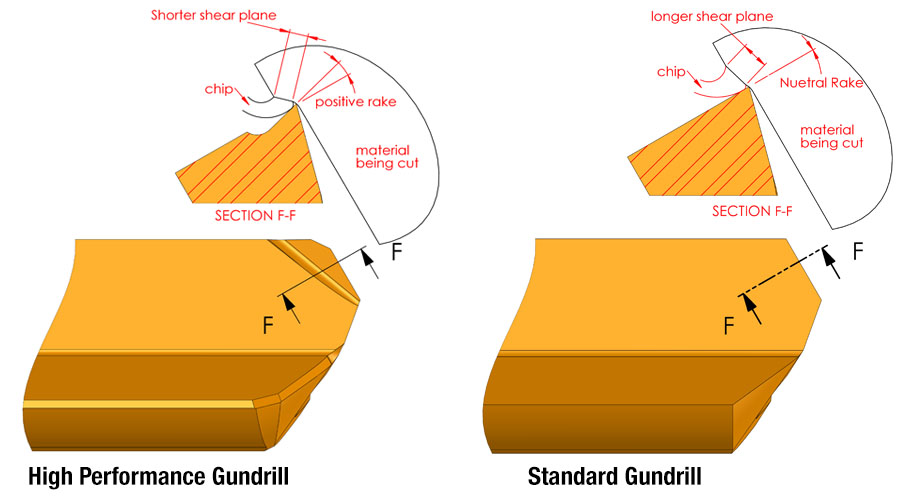

There are 3 main characteristics of the High Performance Gundrill that enables these increased feed rates:

- Positive Rake Face. The first and most important characteristic is a positive rake face that reduces the shear plane length. This results in a reduction of angular force (torque) required to create a manageable chip.

- Finishes and Edge Prep. The second characteristic is finishes and edge prep that we incorporate on this tool is very important in high performance drilling. Star Cutter has invested in this advanced technology that has resulted in tremendous performance.

- Body (Shaft) Material Properties. The third characteristic is our special processing of the cutting tool shaft which increases its strength and resilience.

In addition to the design characteristics of the High Performance Gundrill, there are adjustments in the feeds and speeds that are necessary for proper chip control.

- Chip Formation. The chips produced need to be controlled better than a traditional gundrill operation in rifle barrel machining with the goal of chips that ideally form into a shape that resemble the number 6 (see below). This will avoid having larger chips in the evacuation stream up the flute that can result in catastrophic failure.

- Material Types. Adjustments need to be made to achieve the correct feed rates for the type of material being machined. Star Cutter has successfully proven our technology in the machining of stainless 416, 4150v and 4140 and other materials.

Jeff Michael, Round Tool Engineering Manager

Star Cutter Company has developed into a world leader in the cutting tool industry. Each of our six manufacturing facilities specializes in producing a specific type of product or service: solid carbide cutting tools, carbide blanks and preforms, gundrills, gear cutting tools, and 5-axis CNC tool and cutter grinding machines.

Star Cutter Company has developed into a world leader in the cutting tool industry. Each of our six manufacturing facilities specializes in producing a specific type of product or service: solid carbide cutting tools, carbide blanks and preforms, gundrills, gear cutting tools, and 5-axis CNC tool and cutter grinding machines.