- Home

- Round Tools

- Machines

- Materials

- Services

- About Us

- News & Events

- Careers

- Contact Us

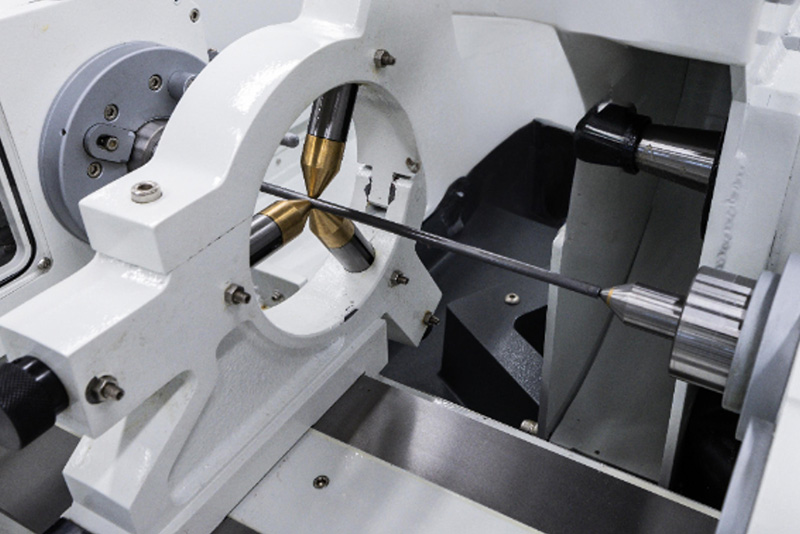

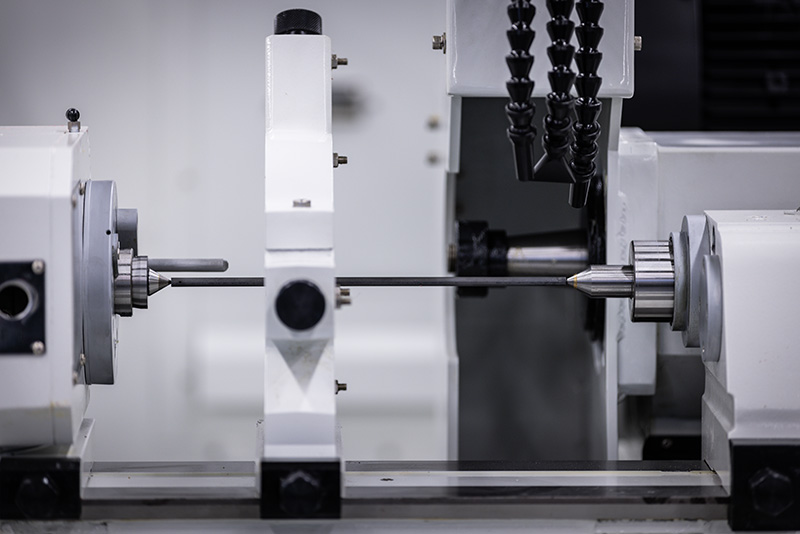

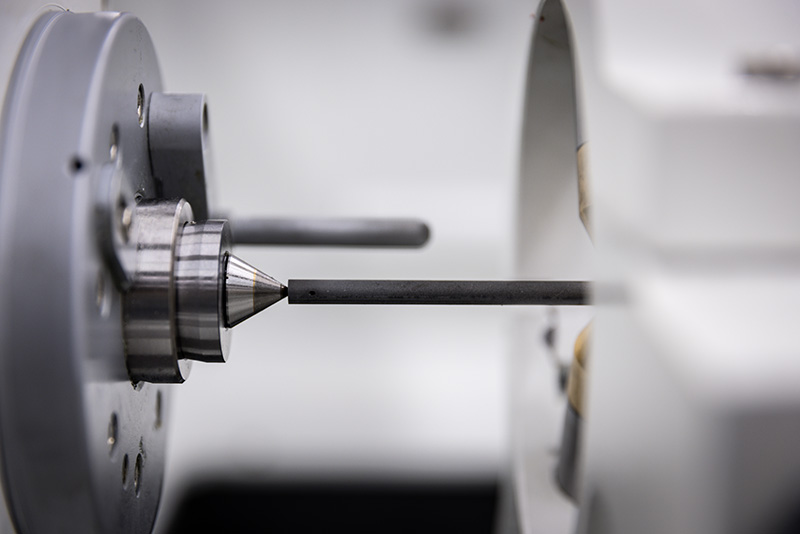

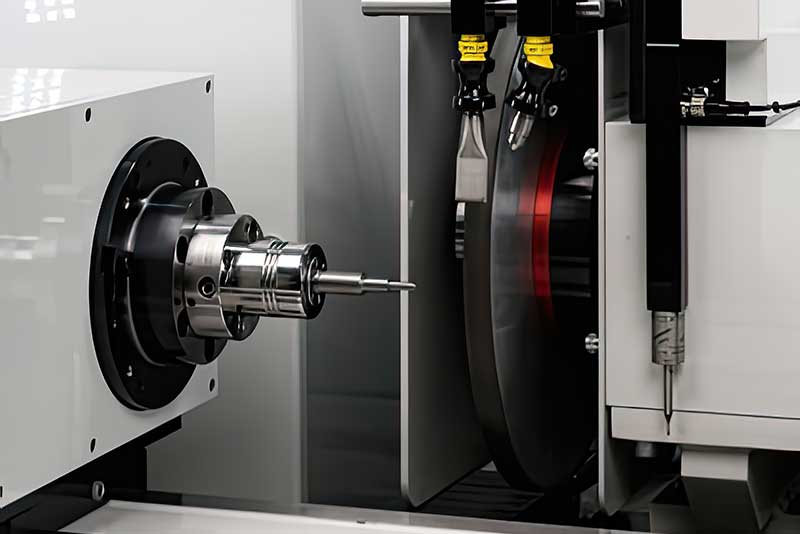

Our versatile TRU TECH universal cylindrical grinders allow for multiple diameters, complex shapes, and angles to be ground. These systems use a headstock comprised of a chuck, or a center with a driver, to hold and rotate the workpiece. This ensures that all diameters ground about the central axis of rotation are concentric with each other and with any other internal diameters that are concentric or “true” with the centers. These machines are ideal for finishing the outside diameter of small cylindrical metal parts requiring a tight tolerance.

The TRU TECH TT1020M delivers exceptional accuracy, flexibility, and operator-friendly simplicity for producing a wide range of precision tooling. Icon-based Conversational Software™ allows operators to program shapes and profiles in minutes, while built-in training and maintenance modules streamline operation, reduce downtime, and help lower total cost of ownership.

| Description | TT1020M |

| Swing Over Table | 10” (254 mm) |

| Distance Between Centers | 20” (508 mm) |

| Maximum Grinding Diameter | 9” (229 mm) |

| Maximum Load Held Between Center | 176 lbs. (80 kg) |

| Center Distance Between Spindle & Slide Table | 5” (127 mm) |

| Quill Travel | 1” (25mm) |

| Center Taper | MT3 (optional MT4) |

| Net Weight (Semi-Enclosed Splash Guard) | 6840 lbs. (3104 kg) |

| Gross Weight | 8380 lbs. (3802 kg) |

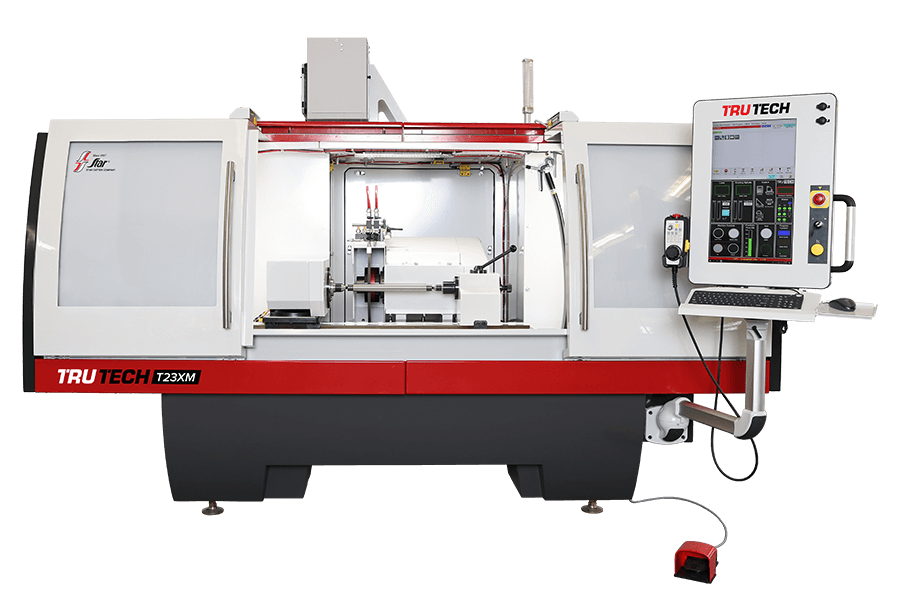

Designed for the bigger jobs, the T23XM is larger, longer, bigger and faster. This machine features an 8” diameter swing and 20” length between centers. Featuring a fully controlled variable speed 10HP spindle motor, it can accommodate up to a 16” diameter x 2” wide grinding wheel.

| Description | T23XM |

| Maximum Grind Length (Distance Between Centers) | 20” (500mm) |

| Maximum Grind Diameter |

X Axis: 20” (500mm) Y Axis: 8” (200mm) |

| Standard Wheel Size | 14” (350mm) Max. |

| Wheel Speed | 500-3000 RPM |

| Maximum Velocity |

X Axis: 50”/Min. Y Axis: 60”/Min. |

| Input Increment | .000010” (0.000254 mm) |

| Accuracy | ±.00010” (0.00254 mm) |

| Repeatability | ±.000050” (0.00127 mm) |

| Wheel Spindle Motor |

7 HP Variable (10 HP Optional) |

| Workhead Motor HP MT-4 |

1.3 HP / 1 KW 50-600 RPM |

| Workhead Angle Adjustment | ±45 Degrees |

| Table Angle Adjustment | ±8 Degrees |

| (Optional) ID Spindle Motor | 1/2 HP |

| Power Requirements | 30 Amps: 208-230V 60 Hz |

| Shipping Dimensions |

Pallet #1: 40”x48”x60” (1016 x 1219 x 1524 mm) Pallet #2: 91”x90”x65” (2311 x 2286 x 1651 mm) |

| Shipping Weight | 10,000 LBS. |

Star Cutter Company has developed into a world leader in the cutting tool industry. Each of our six manufacturing facilities specializes in producing a specific type of product or service: solid carbide cutting tools, carbide blanks and preforms, gundrills, gear cutting tools, and 5-axis CNC tool and cutter grinding machines.

Star Cutter Company has developed into a world leader in the cutting tool industry. Each of our six manufacturing facilities specializes in producing a specific type of product or service: solid carbide cutting tools, carbide blanks and preforms, gundrills, gear cutting tools, and 5-axis CNC tool and cutter grinding machines.

23461 Industrial Park Drive

Farmington Hills, MI 48335

Tel. 248-474-8200

Fax. 248-474-9518

Request a Quote