- Home

- Round Tools

- Machines

- Materials

- Services

- About Us

- News & Events

- Careers

- Contact Us

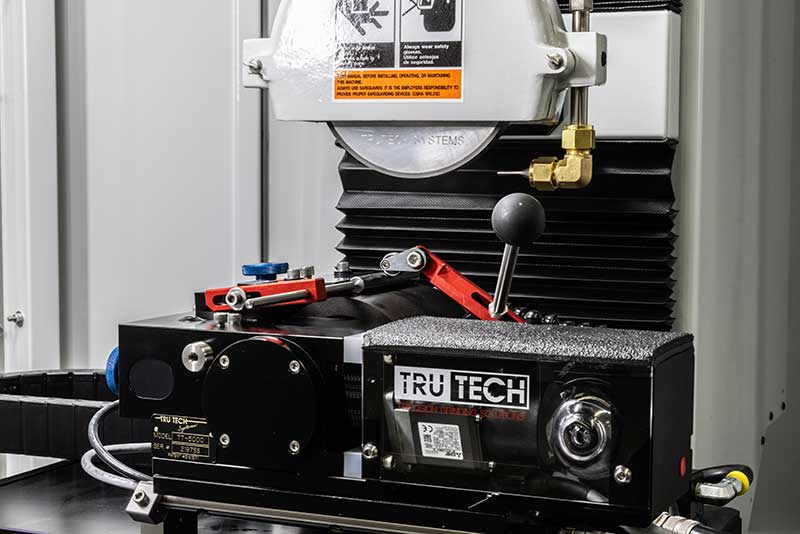

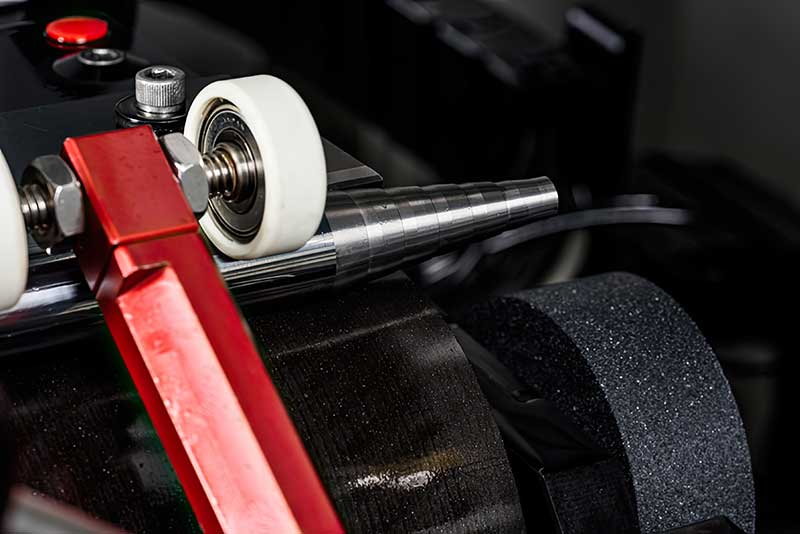

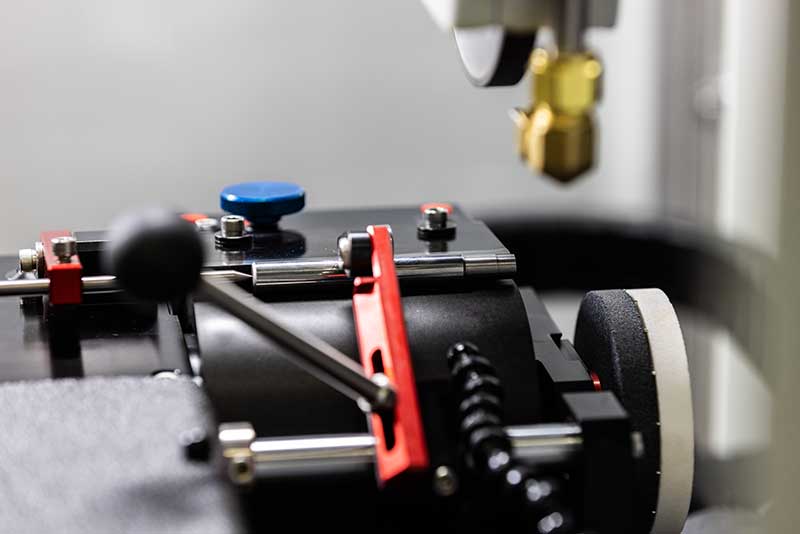

The TRU TECH line of centerless grinders provides precision surface grinding on cylindrical workpieces without the need for centers or chucks. Key to the TRU TECH grinders repeatability and consistency of closely held tolerances is the 3-point work holding capability, enabled by the patented TT5000 and PP8000 Grinding Units. The TRU TECH 3-axis centerless grinders can handle a wide range of workpiece diameters and processes, including plunge, centerless, ID, OD, infeed and form grinding.

Designed with ultra-precision form grinding in mind, the T93XM features 3-point work holding capability offering sub-micron accuracy and incredibly fast, set-up friendly control along with the latest in material technology. The 7,000 lb. T93XM is one of the most stable and rigid precision grinding machines on the market today.

The T93XM-A system adds reliable part automation to this highly precise grinder to maximize the productivity and efficiency of your high-value part profile grinding operations.

| Description | T93XM | T93XM-A |

| Ultra-Precision Grinding Unit | PP-8000 or TT-5000 | PP-8000 or TT-5000 |

| Maximum Grind Length (application specific) | 8” (200 mm) | 10” (254 mm) |

| Maximum Grind Diameter | 3” (75 mm) | 1” (25 mm) |

| Minimum Grind Diameter | Tooling Dependent | Tooling Dependent |

| Maximum Travel |

X Axis: 16” (400 mm) Y Axis: 9” (225 mm) Z Axis: 8.6” (218 mm) |

X Axis: 16” (400 mm) Y Axis: 9” (225 mm) Z Axis: 8.6” (218 mm) |

| Wheel Diameter | 8” (200 mm) Max | 8” (200 mm) Max |

| Standard Spindle HP | 3 HP | 3 HP |

| Spindle RPM (Programmable Software) | 5,000 RPM Max. | 5,000 RPM Max. |

| Maximum Velocity |

X Axis: 50” (1250 mm) / Min. Y Axis: 50” (1200 mm) / Min. |

X Axis: 50” (1250 mm) / Min. Y Axis: 50” (1200 mm) / Min. |

| Input Increment | ±.000010” (0.0001 mm) | ±.000010” (0.0001 mm) |

| Minimum Accuracy | ±.00005”” (0.0013 mm) | ±.00005”” (0.0013 mm) |

| Minimum Repeatability | ±.000025” (0.0006 mm) | ±.000025” (0.0006 mm) |

| Shipping Weight | 5500 LBS. | 5800 LBS. |

| Power Requirements | 200-480V 50/60Hz | 200-480V 50/60Hz |

| Shipping Size |

105” x 73” x 96”H 266cm x 185cm x 246cm |

105” x 73” x 96”H 266cm x 185cm x 246cm |

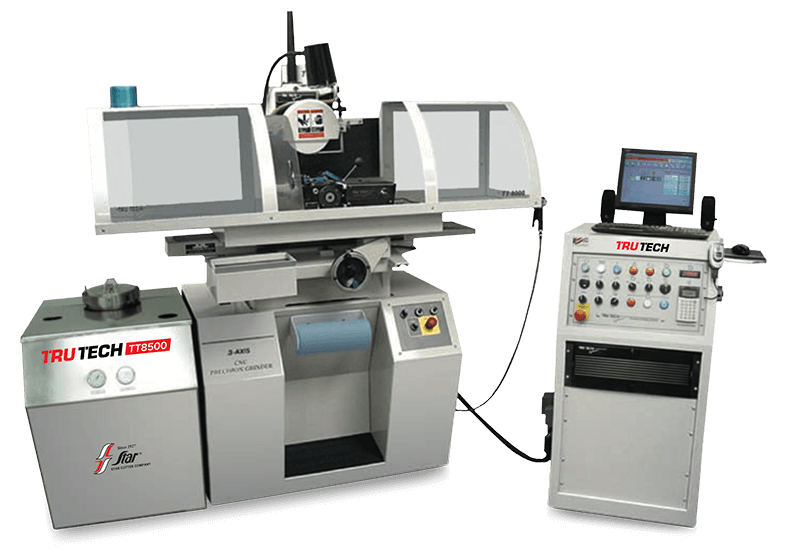

Ideal for carbide blank preparation, the TRU TECH 8500 machine makes easy work of ultra-precise centerless profile grinding projects, whether for a few parts or hundreds.

| Description | TT8500 |

| Ultra-Precision Grinding Unit | TT-5000 |

| Maximum Grind Length (application specific) | 7.5" (191mm) |

| Maximum Grind Diameter | 3” (76 mm) |

| Minimum Grind Diameter | Tooling Dependent |

| Maximum Travel |

X Axis: 18” (457 mm) Y Axis: 10.75” (273 mm) Z Axis: 7.5” (191 mm) |

| Wheel Diameter | 8” (200 mm) Max |

| Standard HP | 2 HP (optional 3 HP) |

| Maximum Velocity |

X Axis: 15” (127 mm) / Min. Y Axis: 15” (127 mm) / Min. |

| Coolant Flow Capacity | Multiple coolant/flow options available |

| Input Increment | ±.000010” (0.0001 mm) |

| Minimum Accuracy | ±.00010”” (0.0025 mm) |

| Minimum Repeatability | ±.000050” (0.00013 mm) |

| Shipping Weight | 2500 LBS. |

| Power Requirements | 20 Amp: 208-230V 60Hz |

| Shipping Size |

Pallet #1: 40”x48”x60” (102 x 122 x 125 cm) Pallet #2: 70”x44”x82” (178 x 112 x 208 cm) |

Star Cutter Company has developed into a world leader in the cutting tool industry. Each of our six manufacturing facilities specializes in producing a specific type of product or service: solid carbide cutting tools, carbide blanks and preforms, gundrills, gear cutting tools, and 5-axis CNC tool and cutter grinding machines.

Star Cutter Company has developed into a world leader in the cutting tool industry. Each of our six manufacturing facilities specializes in producing a specific type of product or service: solid carbide cutting tools, carbide blanks and preforms, gundrills, gear cutting tools, and 5-axis CNC tool and cutter grinding machines.

23461 Industrial Park Drive

Farmington Hills, MI 48335

Tel. 248-474-8200

Fax. 248-474-9518

Request a Quote