- Home

- Round Tools

- Machines

- Materials

- Services

- About Us

- News & Events

- Careers

- Contact Us

The Star NXT CNC 5-axis tool and cutter grinding system provides a large grind zone that enables manufacturers to run both small and large diameter tools, yet is packaged in a cost-effective compact footprint. The NXT leverages the heritage of Star Cutter’s previous grinding machines’ capability reimagined in a modular design that offers easily configurable options and a competitive price point.

The Star NXT CNC 5-axis tool and cutter grinding system provides a large grind zone that enables manufacturers to run both small and large diameter tools, yet is packaged in a cost-effective compact footprint. The NXT leverages the heritage of Star Cutter’s previous grinding machines’ capability reimagined in a modular design that offers easily configurable options and a competitive price point.

Standard platform decreases lead times while enabling quick adaptation to specific customer application requirements

Up to 5-station configuration for quick changeover

Handle tool regrinding to large production

Programmable positioning of tool supports

Standard and extended length tooling rails to accommodate various tool lengths

Eliminates backlash, friction effects and drive vibration as compared to ball screws

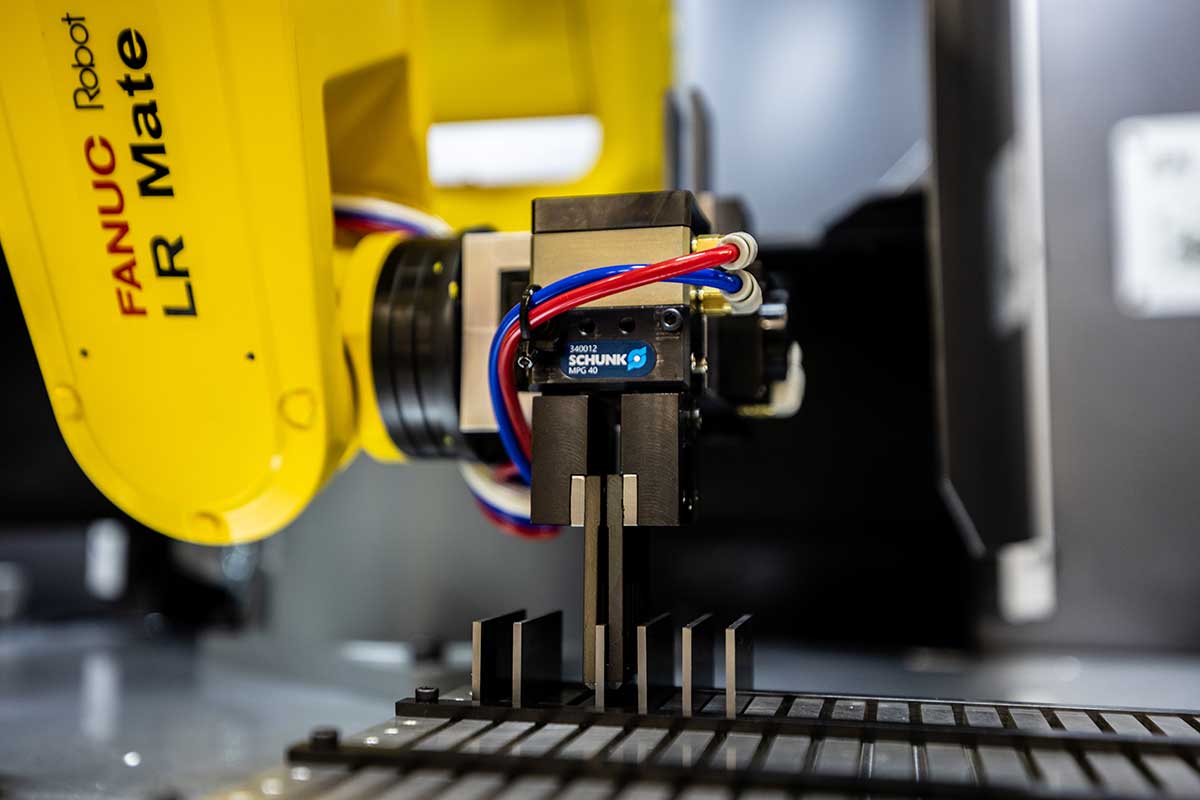

Holds two full pallets and two unload pallets

Automatic blank clamping system eliminates radial and axial runout without special tools

| Part Diameter Range |

Standard Gripper: Accommodates 0.188" - 1.250" (5 - 32mm) Small Gripper: Accommodates ≤ 0.787" (≤ 20mm) Custom Gripper: Accommodates >1.250" (> 32mm) |

| Part Length | Auto load parts up to 12” (305 mm) |

| Part Weight | Auto load single parts up to 6.5lb (3kg) or dual parts up to 3.3lb (1.5kg) |

| Part Pallets | 4; 2 for blanks, 2 for finished parts |

| Pallet Density |

0.188" - 0.275" (3.7 - 7.0mm) - 221 parts/pallet 0.275" - 0.512" (>7 - 13mm) - 130 parts/pallet 0.512" - 0.787" (>13 - 20mm) - 63 parts/pallet 0.787" - 1.26" (>20 - 32mm) - 30 parts/pallet |

NXT grinders feature the latest Flexium+ CNC solution with NUMROTO 4.2.0, a comprehensive software package for producing and resharpening a wide range of tools. Even the most complex shapes can be easily programmed and executed.

A complete NUMROTO solution includes many functions to manufacture or regrind a tool as efficiently as possible. With functions such as 3D simulation, extensive and precise probe cycles for tool and wheel, in-process wheel dressing, job control, creation of elevation drawings, adaptive grinding and more, the system can be expanded per user needs.

Based on current Windows systems, NUMROTO can be integrated into the company network. Central storage and administration of part programs and extended back-up functions are therefore easy to implement.

To serve the medical grinding community, Star Cutter and Hexagon Manufacturing Intelligence have an exclusive partnership where ESPRIT CAM software is pre-packaged to run the Star Cutter 5-axis software right out of the box. ESPRIT is a high-performance CAM system for CNC programming, optimization and simulation. Well known for its machine-optimized, edit-free G-code (toolpath), ESPRIT leverages a digital twin simulation platform to model the finished part, tools, and CNC machine. AI-based algorithms eliminate manual data input and provide machine operators with greater assurance of what will happen on the shop floor. The result – simplified programming, increased tool life and utilization, reduced cycle times and improved productivity.

This packaged solution is perfect for manufacturers of complex medical tooling, such as hip rasps, rotary files, bone files and drills, etc. ensuring that your machine will launch quickly and keep running at top efficiency.

Star Cutter Company has developed into a world leader in the cutting tool industry. Each of our six manufacturing facilities specializes in producing a specific type of product or service: solid carbide cutting tools, carbide blanks and preforms, gundrills, gear cutting tools, and 5-axis CNC tool and cutter grinding machines.

Star Cutter Company has developed into a world leader in the cutting tool industry. Each of our six manufacturing facilities specializes in producing a specific type of product or service: solid carbide cutting tools, carbide blanks and preforms, gundrills, gear cutting tools, and 5-axis CNC tool and cutter grinding machines.

23461 Industrial Park Drive

Farmington Hills, MI 48335

Tel. 248-474-8200

Fax. 248-474-9518

Request a Quote