As a rule, gundrills wear in three distinct areas: at the point, the face, and the outer diameter. After regrinding, each of these should be returned to their original factory specifications. The area most commonly missed is the outer diameter, which is often left in less than pristine condition and should not be used as-is.

A good indicator of this is a noticeable difference in tool life as compared to a new tool. Whether new or reconditioned, however, Star SU recommends that customers attempting to optimize machining conditions do so in a scientific manner, changing one parameter or cutting tool attribute at a time and documenting the results until the desired outcome is achieved.

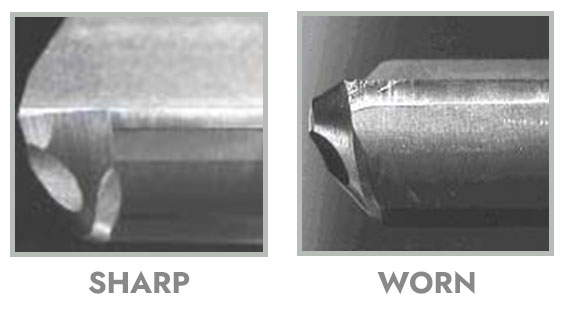

The drill point is the first place to inspect. When 1/2 to 2/3 of the cutting edge shows wear the tool should be reground. If tool life is less than expected and this is the primary failure mode, there is a good possibility that the drill has the incorrect geometry.

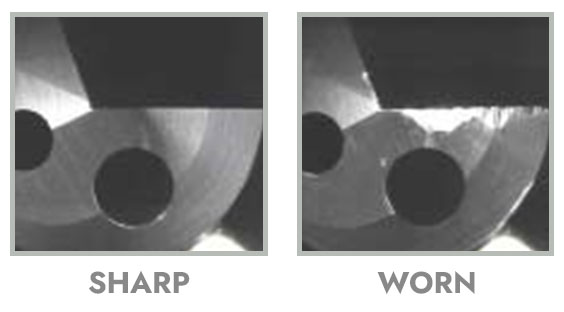

If a gundrill needs to be pulled prematurely due to corner rounding, the cutting speeds are probably too high or there is an alignment problem. Depending on the workpiece material, decreasing the spindle rpm can help to improve tool life, as will increasing the coolant concentration when using water-soluble cutting fluids

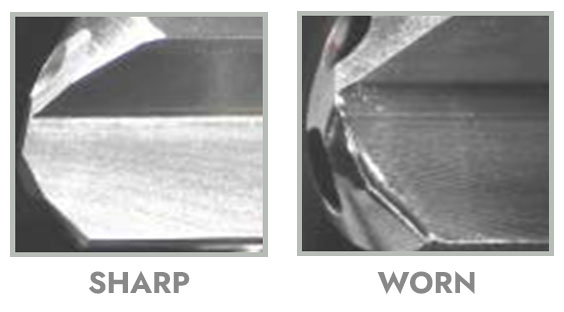

Premature face wear can be caused by cratering or built-up edge (BUE). Several potential problems exist. For starters, be sure to follow the manufacturer’s feed and speed recommendations for the workpiece material—many shops are too conservative and tend to decrease these values at the first sign of trouble. Coolant pressure and lubricity should also be increased if possible. Otherwise, increasing the drill’s outside angle may help improve tool life,

Star Cutter Company has developed into a world leader in the cutting tool industry. Each of our six manufacturing facilities specializes in producing a specific type of product or service: solid carbide cutting tools, carbide blanks and preforms, gundrills, gear cutting tools, and 5-axis CNC tool and cutter grinding machines.

Star Cutter Company has developed into a world leader in the cutting tool industry. Each of our six manufacturing facilities specializes in producing a specific type of product or service: solid carbide cutting tools, carbide blanks and preforms, gundrills, gear cutting tools, and 5-axis CNC tool and cutter grinding machines.

23461 Industrial Park Drive

Farmington Hills, MI 48335

Tel. 248-474-8200

Fax. 248-474-9518