- Home

- Round Tools

- Machines

- Materials

- Services

- About Us

- News & Events

- Careers

- Contact Us

Rifle barrels are made a number of ways, but the most common method starts with a gundrill, followed by reaming, and finally rifling with a button. Other popular methods would include hammer forge, honing, or cut rifling. No matter the method, drilling a deep hole is necessary. Star SU reamers, drills, and buttons focus on geometrical quality and better finishes.

Surface and edge conditions are very important in creating deep holes such as the rifle barrel. Working in conjunction with coating partners, today’s deep hole products are performing in quality and productivity like never before.

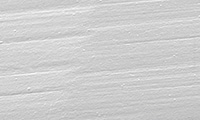

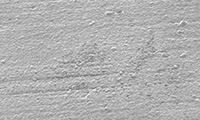

The new coatings Star SU utilizes (top), vastly improve smoothness versus more common coatings (bottom). Each imperfection in the coating can be a propagation point for wear. Minimizing the imperfections maximizes performance consistency whether coated or not.

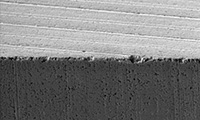

Edge conditions are equally important. When magnified, carbide edges are jagged. Rounding those edges allow the coatings to form properly between the ground surfaces of the cutting tool at the edge. This slight rounding keeps the coating intact and stops premature adhesion wear. Pictures below illustrate this.

For more information on gundrilling click here: http://bit.ly/2CTH9D6

Jeff Michael – Engineering Manager, Round Tools

Star Cutter Company has developed into a world leader in the cutting tool industry. Each of our six manufacturing facilities specializes in producing a specific type of product or service: solid carbide cutting tools, carbide blanks and preforms, gundrills, gear cutting tools, and 5-axis CNC tool and cutter grinding machines.

Star Cutter Company has developed into a world leader in the cutting tool industry. Each of our six manufacturing facilities specializes in producing a specific type of product or service: solid carbide cutting tools, carbide blanks and preforms, gundrills, gear cutting tools, and 5-axis CNC tool and cutter grinding machines.

23461 Industrial Park Drive

Farmington Hills, MI 48335

Tel. 248-474-8200

Fax. 248-474-9518

Request a Quote