- Home

- Round Tools

- Machines

- Materials

- Services

- About Us

- News & Events

- Careers

- Contact Us

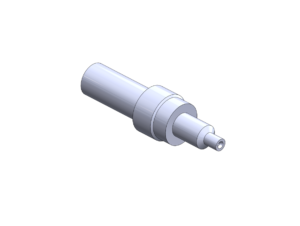

One goal of the H.B. Advantage is to save our customers time when machining our blanks. By providing near net shape blanks, we can reduce the overall grinding time required to finish the blanks. We do this by adding features such as diameters, flutes, pockets, flats, coolant holes, etc. All machining is done in the green state before the carbide is hardened and is performed using much higher feed rates than conventional grinding. The combination of added features and reduced stock provides our customers with blanks that have less material to be removed during finishing, which leads to reduced cycle times and costs.

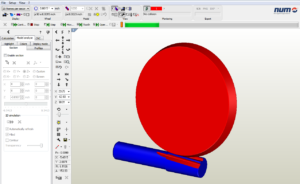

H.B. Carbide uses model based machining methods, so we encourage our customers to share 3D models of complex parts in order to achieve the closest near net shape blanks as possible. We use Star’s Numroto based grinding machines, so when possible, we utilize customer’s Numroto grinding programs to duplicate and provide the most complex fluting features as accurately as possible.

Chuck Crane

Product Manager, H.B. Carbide Company

To learn more about our lineup of carbide blacks and preforms click here.

Star Cutter Company has developed into a world leader in the cutting tool industry. Each of our six manufacturing facilities specializes in producing a specific type of product or service: solid carbide cutting tools, carbide blanks and preforms, gundrills, gear cutting tools, and 5-axis CNC tool and cutter grinding machines.

Star Cutter Company has developed into a world leader in the cutting tool industry. Each of our six manufacturing facilities specializes in producing a specific type of product or service: solid carbide cutting tools, carbide blanks and preforms, gundrills, gear cutting tools, and 5-axis CNC tool and cutter grinding machines.

23461 Industrial Park Drive

Farmington Hills, MI 48335

Tel. 248-474-8200

Fax. 248-474-9518

Request a Quote