Manufacturing accuracy and precision are crucial to the performance and reliability required of a firearm. Gun manufacturers need to ensure they are working with the highest quality cutting tools that are optimized for each application, and capable of producing the complex geometries and tolerances driven by the firearms industry.

Star Cutter has years of experience in developing optimized hole making and drilling tools for the production of firearm components machined from 4140 and 4150V steels, 410 & 416 stainless steels, Stellite, and 7075 aluminum.

Material: 4140; 4150V

Speed: 4,400 – 4,800 RPM

Feed: 2.75 – 3.75 inches/min

Regrinds: 5 – 10

Tool life: 200 – 400 barrels

(depending on material quality)

Material: 4140; 4150V

Speed: 5,000 – 5,500 RPM

Feed: 7 – 10 inches/min

Tool life: 200 – 500 barrels

(depending on material quality)

Material: 416 Stainless Steel

Speed: 5,000 – 5,500 RPM

Feed: 2.75 – 3.75 inches/min

Tool life: 200 – 300 barrels

(depending on material quality)

Double Contour Specialty Design for Excellent Part TIR Control

Material: 416 Stainless Steel

Speed: 5,000 – 5,500 RPM

Feed: 7 -10 inches/min

Tool life: 500 – 600+ barrels

(depending on material quality)

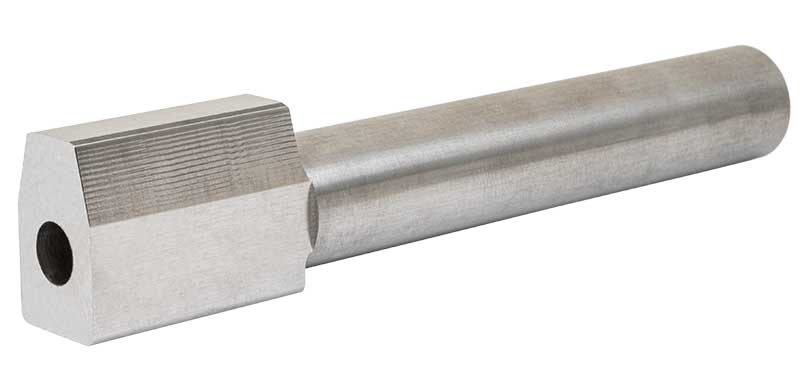

Material: 4150V

Speed: 800 – 1000 RPM

Feed: 4 – 8 inches/min

Length of Cut: 18 inches

Tool life: 2,000 – 4,000 barrels

(depending on material quality)

First Pass

Material: 158 Steel

Diameter: 4.128 mm

Speed: 4,750 – 5,250 RPM

Feed: 1.90 – 3.156 inches/min

Tool life: 275 – 325 parts

Second Pass

Material: 158 Steel

Diameter: 4.120/1.586 mm

Speed: 4,750 – 5,250 RPM

Feed: 1.00 – 1.60 inches/min

Tool life: 475 – 525 parts

Material: 410 Stainless Steel

Speed: 4,000 – 5,000 RPM

Depth of Cut: 5.50 inches

Feed: 40 inches/min

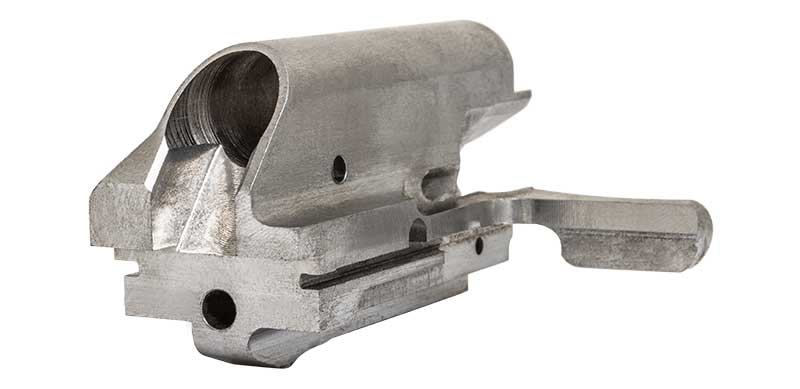

Material: 4140

Speed: 3,000 RPM

Feed: 3.50 inches/min

Depth of Cut: 3.50 inches

Tool Life: 725 – 775 barrels

(depending on material quality)

Material: 7075-T6

RPM: 1,940

Size: ø 1.805

Feed: 15.52 inches/min

Material: 7075-T6

Size: ø 30.340

RPM: 1,118

IPM: 35.25

Positional Errors: ≤ 0.0003”

(design change implemented tool in production.)

Tool life: ≥ 3,000 parts

Star Cutter Company has developed into a world leader in the cutting tool industry. Each of our six manufacturing facilities specializes in producing a specific type of product or service: solid carbide cutting tools, carbide blanks and preforms, gundrills, gear cutting tools, and 5-axis CNC tool and cutter grinding machines.

Star Cutter Company has developed into a world leader in the cutting tool industry. Each of our six manufacturing facilities specializes in producing a specific type of product or service: solid carbide cutting tools, carbide blanks and preforms, gundrills, gear cutting tools, and 5-axis CNC tool and cutter grinding machines.

23461 Industrial Park Drive

Farmington Hills, MI 48335

Tel. 248-474-8200

Fax. 248-474-9518