For machining holes with a relatively large diameter to depth ratio, Star Cutter offers a variety of solutions, all providing excellent diameter control and straightener in a variety of workpieces and materials.

These drills are designed to drill straight deep holes from solid part condition while holding excellent finishes. Capable of achieving precision holes in a single pass, Star gundrills also offer consistent hole-to-hole reproduction. These drills can create bottom-hole configurations and assist in burr-free intersections.

The gundrill requires high-pressure coolant through the tool, keeping the cutting edges lubricated and providing adequate chip evacuation down the flute channel. The design of the single-lip, straight deep “V” flutes and high coolant pressure allows for fast, consistent penetration without the need for pecking.

Due to the point not being on center, the tool requires either a bushing or a pilot hole starting support. Once into the cut, the tool is self-piloting.

Special designs, carbide grades and coatings selections are available to optimize tool performance based upon the application.

A special cutting drill with an added rear contour configuration acts like a guide pad while the drill remains in the bushing, keeping the tool on location. Once the drill is in the cut, these guide pads continue to force the tool to cut a straight path throughout the operation.

The success of this tool is based upon a combination of its positive rake face, edge preps and finishes in conjunction with establishing speeds and feeds for proper chip control.

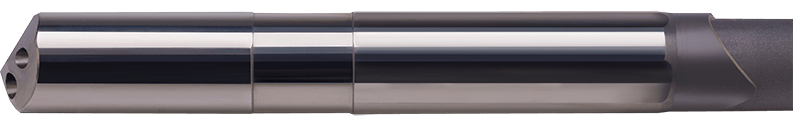

Star Cutter’s solid carbide gundrills feature a two-piece construction design. The tip and body are a solid piece of carbide based into the drive/shank with the flute ground down the length of the head and body. The absence of the braze joint at the head/body transition eliminates the possibility of coolant obstructions while adding significant strength to the tool, which can allow a 2x – 3x higher feed rate. These tools can be designed with special end forms to meet your custom requirements. Additionally, special coatings are chosen, based on the application, to enhance overall tool performance.

A special cutting drill with an added rear contour configuration acts like a guide pad while the drill remains in the bushing, keeping the tool on location. Once the drill is in the cut, these guide pads continue to force the tool to cut a straight path throughout the operation.

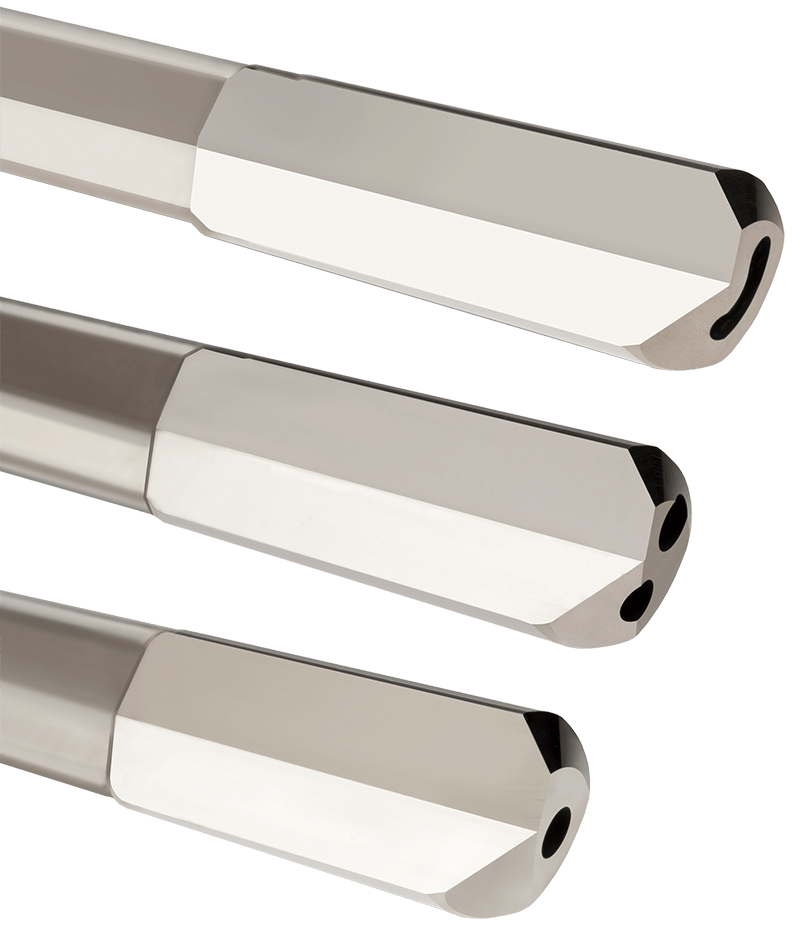

This patented product boasts a unique design with strategic placement of coolant holes that helps supply adequate coolant to the cutting edge while entering and exiting the cut. This also assists with breakthrough on intersecting holes and/or enter irregular surfaces without premature wear. As with all gundrills, the double jet style ensures straightness, concentricity, size and finishes.

Double crimp gundrills are created by crimping the same tube used for the single flute gundrill, only crimping it twice, 180° apart. This creates shallower flute channels than the single flute, which limits the type of materials to be drilled based on the chip size generated, but also minimizes the coolant turbulence at the head/body position. Additionally, the flutes being equally swaged 180° apart allow for much greater rigidity, enabling higher feed rates. This is obtained by two cutting edges opposed to one another, and geometry angles ground to precise dimensions.

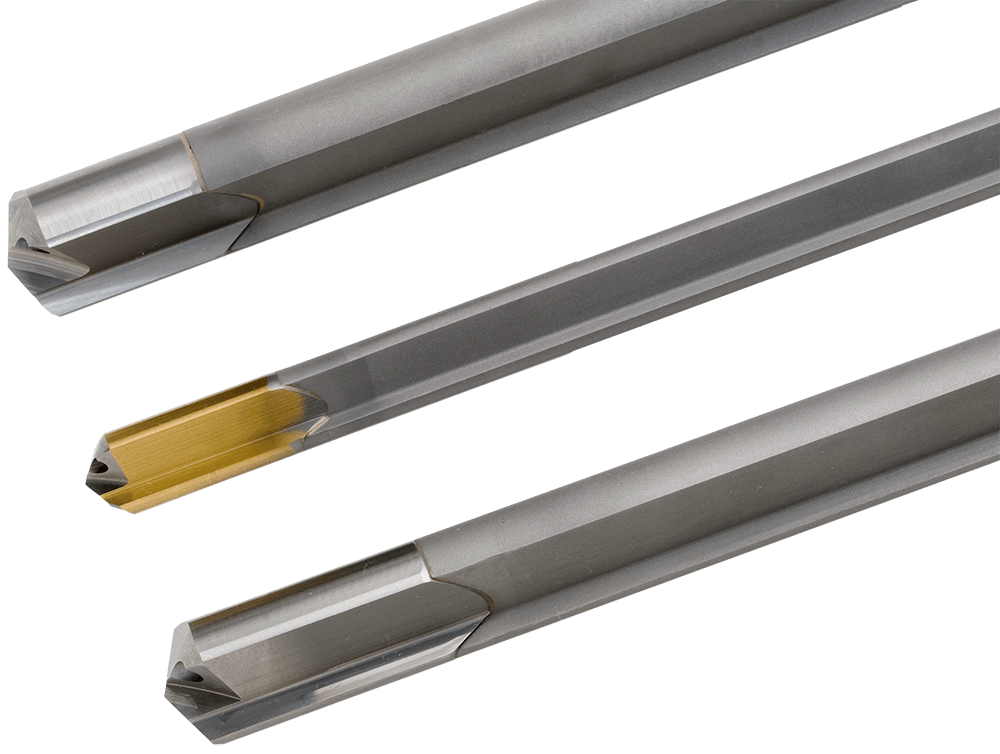

The two-flute, two-holed “Milled Style Gundrill” is used for high-penetration, deep-hole iron applications including gray, cast and CGI. This tool is engineered with a solid steel body, milled flutes, and coolant holes produced internally to allow for optimum coolant flow to the tip. The results yield an incredibly ridged tool, reducing body deflection at higher RPMs to enable higher feed rates. It is applied where length to diameter ratios dictate a more rigid tool due to the lack of whip guides.

A special cutting drill with an added rear contour configuration acts like a guide pad while the drill remains in the bushing, keeping the tool on location. Once the drill is in the cut, these guide pads continue to force the tool to cut a straight path throughout the operation.

Featuring sculptured flute geometry and polished beyond the cutting area flutes, these drills provide superior chip control and enhanced chip evacuation. Geometries are based on the materials being machined and applying proper speeds and feeds result in increased tool life and improved chip evacuation.

Our capability to manufacture high precision rifle buttons made to your requirements allows Star Cutter to offer a high quality, competitive cost alternative while providing performance consistency.

Firearm push and pull reamers are manufactured from our special carbide grades chosen during the design phase, ensuring high quality cutting edges.

Star Cutter Company has developed into a world leader in the cutting tool industry. Each of our six manufacturing facilities specializes in producing a specific type of product or service: solid carbide cutting tools, carbide blanks and preforms, gundrills, gear cutting tools, and 5-axis CNC tool and cutter grinding machines.

Star Cutter Company has developed into a world leader in the cutting tool industry. Each of our six manufacturing facilities specializes in producing a specific type of product or service: solid carbide cutting tools, carbide blanks and preforms, gundrills, gear cutting tools, and 5-axis CNC tool and cutter grinding machines.

23461 Industrial Park Drive

Farmington Hills, MI 48335

Tel. 248-474-8200

Fax. 248-474-9518