- Home

- Round Tools

- Machines

- Materials

- Services

- About Us

- News & Events

- Careers

- Contact Us

For machining holes with large diameter-to-depth ratio in a single pass without the need of peck cycles, Star Cutter offers a variety of solutions that provide excellent diameter and TIR from entry to exit in a variety of workpieces and materials.

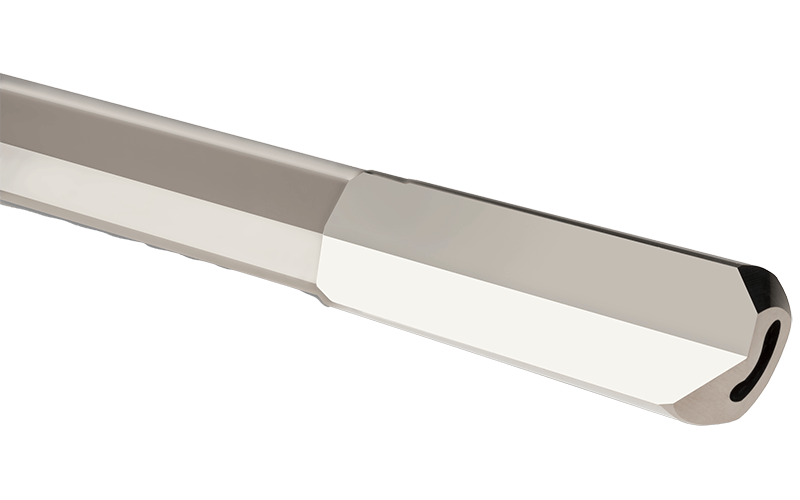

The Single Flute Gundrill, with its ability to machine very accurate deep holes and hold excellent part surface finishes, was originally developed for gun barrel manufacturing. Today, this tool is designed for deep-hole drilling in virtually any material.

The gundrill is designed to drill holes from solid part conditions with the ability to create bottom hole configurations and assist in burr-free intersections. The gundrill will achieve precision holes in one pass without the pecking cycles.

The gundrill requires high-pressure coolant delivered internally through the tool, keeping the cutting edges and guide pads lubricated, while providing the coolant to flush the chips down the flute channel.

Special designs, carbide, and coating selections are available based on application review to optimize the tools performance.

The gundrill has a single cutting edge that requires either a traditional bushing or pilot hole to start. Once the gundrill is supported, the tool is self-piloting through the remainder of the cut. The size relationship between the gundrill and the pilot hole or bushing is critical.

Due to the tool having a flexible steel crimped body, the diameter depth ratio for unsupported lengths without the use of predrilled holes or machine guide supports is 40:1. This is required to control the tool body whipping and vibrations to the cutting edge, preventing catastrophic failures.

A special cutting drill with an added rear contour configuration acts like a guide pad while the drill remains in the bushing, keeping the tool on location. Once the drill is in the cut, these guide pads continue to force the tool to cut a straight path throughout the operation.

The success of this tool is based upon a combination of its positive rake face, edge preps and finishes in conjunction with establishing speeds and feeds for proper chip control.

Expedited delivery of gundrills! With drilling being the most common machining operation, having access to quality Gundrills in a timely manner is of utmost importance. Keep your operations running smoothly with Star Cutter’s Custom Express and In-Stock Drill programs, designed for quick delivery of tools.

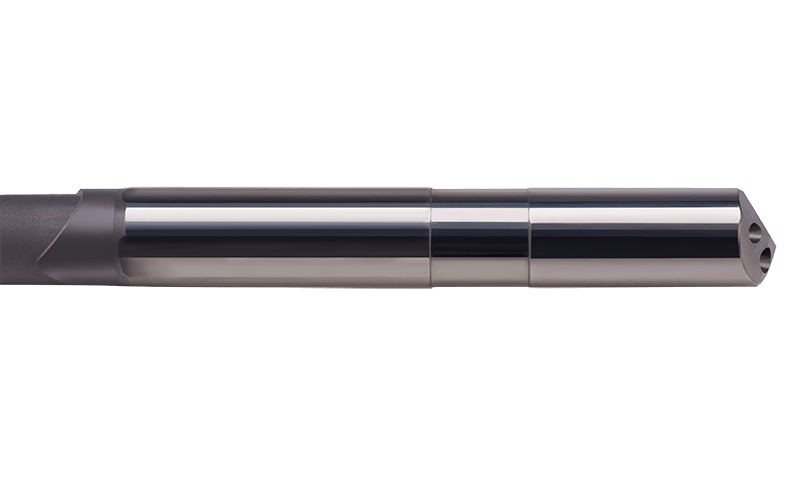

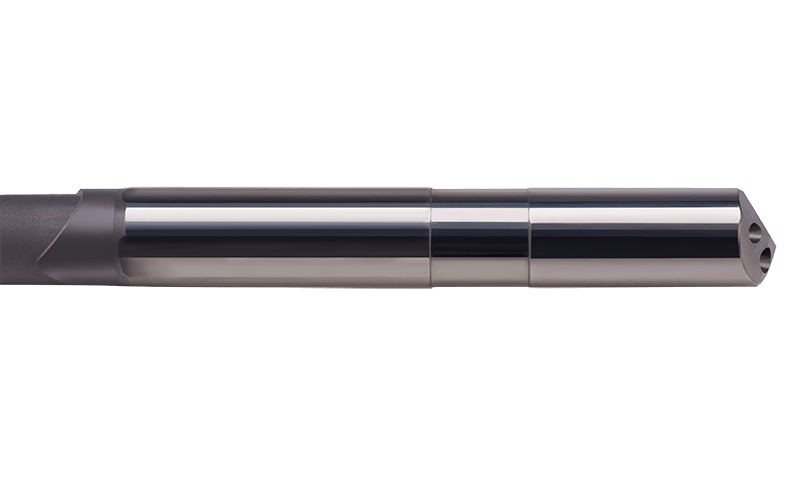

The Solid Carbide Gundrill is manufactured as a one-piece solid carbide head and body that can be brazed into a steel shank if needed. This design results in a very rigid product that optimizes the tools performance by minimizing the amount of whip and/or vibrations that would typically be experienced with a brazed construction standard Single Flute Gundrill.

The rigidity of this product makes this tool ideal for use in gundrill machines, CNC machining centers, lathes and Swiss machines, as this tool does not require whip guide supports for applications up to 80:1 diameter-to-length ratios.

The Solid Carbide Gundrill can also be run at higher speed and feed rates resulting in significant cycle time reduction. The strength of the Solid Carbide Gundrill design can help achieve performance improvement by 100% to 200% as compared to conventional gundrills.

The Solid Carbide Gundrill does require a bushing or pilot hole prior to the start of the cut.

These tools can be designed with special end forms to meet your custom requirements. Additionally, special coatings are chosen, based on the application, to enhance overall tool performance.

A special cutting drill with an added rear contour configuration acts like a guide pad while the drill remains in the bushing, keeping the tool on location. Once the drill is in the cut, these guide pads continue to force the tool to cut a straight path throughout the operation.

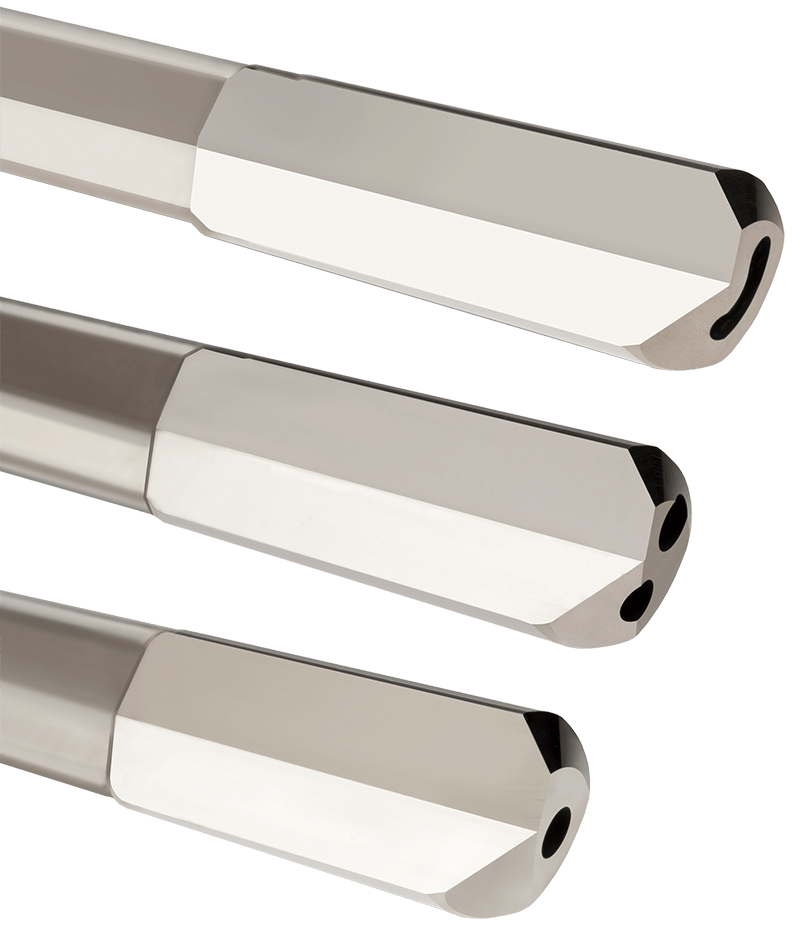

Star Cutter, calling on its years of experience in gundrilling, developed an original patented product known as the Double Jet Gundrill.

During the entry and exit of the workpiece, the carbide of a gundrill is subjected to its highest stresses due to lack of lubricity and coolant flow to the cutting edges. The double jet was designed to combat this condition through unique placement of the coolant holes, capable of supplying significantly higher amounts of coolant to the cutting edges during this critical phase.

This is particularly beneficial in machining steel forgings, powdered metal, exotic materials, and high-temperature alloys whose environments are normally detrimental to tool longevity.

The Double Jet Gundrill is also able to break into, and cross, intersecting holes and/or enter irregular surfaces without premature wear.

The high-pressure coolant stream across the platform cools the cutting zone unlike normal gundrills. This can substantially increase the tool life by reducing crater wear on the difficult to machine materials and can also help reduce a burr on the breakout.

As with all gundrills, excellent straightness, concentricity, size, and superior finishes are obtained.

The term double crimp refers to a two-flute design for maximizing cycle time over the traditional Single Flute Gundrill. Specially designed geometries on the Double Crimp Gundrill include dual cutting edges to increase the feed rate (usually double) over the Single Flute Gundrill. This allows for substantial increases in feed rate. The body of the tool is manufactured using tubular seamless steel that is formed to allow for maximum coolant flow which provides excellent chip evacuation. This makes the tool ideal for the machining of non-ferrous materials and some cast iron applications.

The Double Crimp Gundrill, like the Single Flute Gundrill, requires either a traditional bushing or pilot hole to start. Once the gundrill is engaged, the tool then machines the deep portion of the hole at accelerated feed rates.

The tolerance between the gundrill and the pilot hole or bushing is critical.

This tool can be used in conventional gundrill machines, lathes, and machining centers.

This Star Cutter Two-Flute Two-Hole Milled-Style Gundrill is engineered with an extruded steel body around a controlled center hole that will act as a coolant passage. The two flutes are added during a precision ground milling process and are adaptable to variable lengths based on application requirements. Carbide lengths, contours, and features are also reviewed for each application.

The rigid extruded steel body is what differentiates the Two-Flute Two-Hole Milled Gundrill from the Double Crimp Gundrill.

The two included cutting blades allow for greater penetration rates, thereby reducing cycle times in deep hole applications as compared to single flute traditional gundrills. This tool is effectively used in many cast irons deep hole applications. Proven applications include straight grade grey cast, ductile, austempered (AGI and ADI), and compacted graphite iron (CGI).

Star Cutter Company has perfected a two-flute two-hole milled style double contour design utilizing an extended length carbide head with double contour geometry. This special tool design has proven results in reducing the tool drift for the depth of cut. This results in excellent TIR readings from entry to the exit of the part. This is accomplished by combining our special contours and an additional rear piloting contour configuration that performs like extra guide pads forcing the tool on location. Once in the cut, these guide pads continue to force the tool to cut a straight path for the remainder of cut.

This special design is an excellent option when machining from both sides of a part to reduce the mismatch in the center where the two drill bore meet.

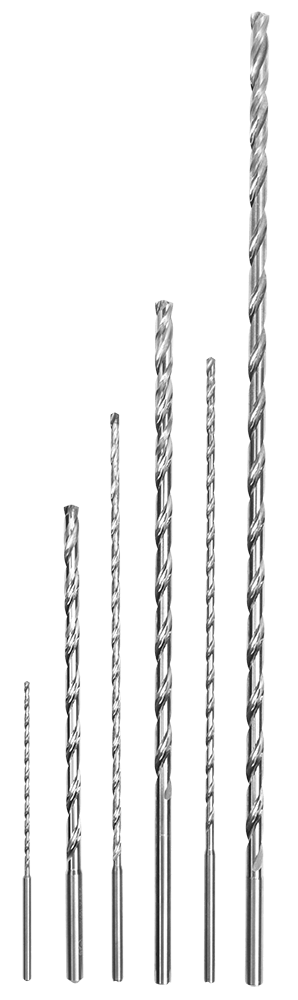

Star Cutter Solid Carbide Custom Deep Hole Twist Drills feature sculptured flute geometry and are polished beyond the cutting area flutes resulting in superior chip control and enhanced chip evacuation. Each tool is custom designed using best practices for geometries based on the ISO material machined and custom lengths determined by the depth of cut part to meet all the print requirements. These special designs offer an excellent choice to increase the pilot hole depths for cycle time reductions.

Firearm push and pull reamers are manufactured from our special carbide grades chosen during the design phase, ensuring high quality cutting edges.

Star High Precision Rifle Buttons are made to SAAMI specifications or your specific requirements.

Advantages:

Star Cutter Company has developed into a world leader in the cutting tool industry. Each of our six manufacturing facilities specializes in producing a specific type of product or service: solid carbide cutting tools, carbide blanks and preforms, gundrills, gear cutting tools, and 5-axis CNC tool and cutter grinding machines.

Star Cutter Company has developed into a world leader in the cutting tool industry. Each of our six manufacturing facilities specializes in producing a specific type of product or service: solid carbide cutting tools, carbide blanks and preforms, gundrills, gear cutting tools, and 5-axis CNC tool and cutter grinding machines.

23461 Industrial Park Drive

Farmington Hills, MI 48335

Tel. 248-474-8200

Fax. 248-474-9518

Request a Quote