- Home

- Round Tools

- Machines

- Materials

- Services

- About Us

- News & Events

- Careers

- Contact Us

Star Cutter offers three unique coolant hole configurations:

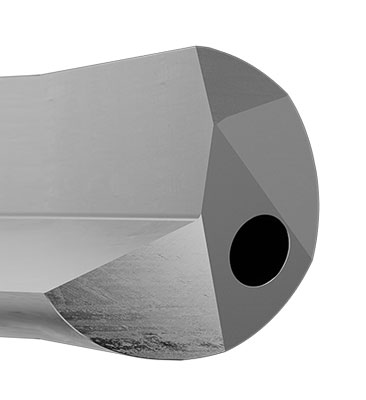

Used in general-purpose applications where coolant pressure is adequate and the machining environment presents no difficulties.

This coolant hole is recommended for cutting diameters of 0.376″ [9.54mm] and larger. The design supports higher coolant flow, improving chip evacuation.

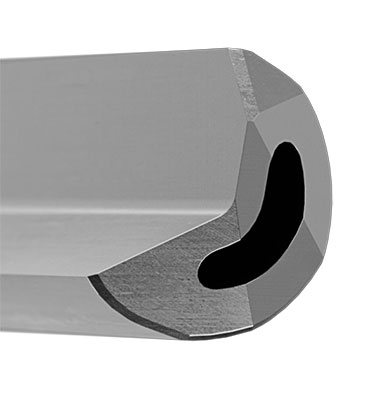

This style is recommended for cutting diameters under 0.375″ [9.53mm]. The extruded shapes help to increase coolant flow, thus allowing for better chip evacuation. This configuration should be used when lubricity is minimal or where heat is a concern.

Cutting Fluids

High-pressure coolant (HPC) aids in chip evacuation and helps keep the cutting tool cool and well-lubricated. It is a must for all gundrill operations.

Three types of coolant (cutting fluid) are used in machining operations: straight or neat oil, synthetics and semi-synthetics, and water-soluble or emulsion-style fluids.

As a rule, straight oil provides the best tool life, provided it contains sulfur and/or chlorine. Sulfur’s anti-weld properties help prevent built-up edge (BUE) on the cutting tool, while chlorine acts as a lubricant, further enhancing chip evacuation.

Water-soluble cutting fluids are made up of as much as 50% mineral oil, with the remainder consisting of water, chemicals, and extreme-pressure (EP) additives to enhance lubrication. While these fluids cool more efficiently and are better for the environment than oil-based alternatives, they can reduce tool longevity.

Similarly, synthetic and semi-synthetic fluids are chemical formulations with minimal or no mineral oil content. These fluids typically necessitate concentrations of at least 8%, with 10% being optimal. It is important to note that synthetic cutting fluids may lead to a considerable reduction in tool life when compared to straight oil.

Recommended Coolant Pressures

| Size (inches) | Size (mm) | PSI | Bar |

| .078-.155 | 1.98-3.94 | 1500 | 100 |

| .156-.186 | 3.95-4.72 | 1300 | 90 |

| .187-.217 | 4.73-5.51 | 1150 | 80 |

| .218-.249 | 5.52-6.32 | 1050 | 70 |

| .250-.311 | 6.33-8.00 | 925 | 60 |

| .312-.374 | 8.01-9.50 | 775 | 50 |

| .375-.436 | 9.51-11.07 | 675 | 45 |

| .437-.499 | 11.08-12.69 | 600 | 40 |

| .500-.561 | 12.70-14.25 | 525 | 35 |

| .562-.624 | 14.26-15.85 | 500 | 20 |

| .625-.686 | 15.86-17.45 | 450 | 30 |

| .687-.749 | 17.46-19.04 | 425 | 28 |

| .750-.874 | 19.05-22.20 | 400 | 26 |

| .875-.999 | 22.21-25.39 | 350 | 24 |

| 1.000 and up | 25.40 and up | 300 | 20 |

Star Cutter Company has developed into a world leader in the cutting tool industry. Each of our six manufacturing facilities specializes in producing a specific type of product or service: solid carbide cutting tools, carbide blanks and preforms, gundrills, gear cutting tools, and 5-axis CNC tool and cutter grinding machines.

Star Cutter Company has developed into a world leader in the cutting tool industry. Each of our six manufacturing facilities specializes in producing a specific type of product or service: solid carbide cutting tools, carbide blanks and preforms, gundrills, gear cutting tools, and 5-axis CNC tool and cutter grinding machines.

23461 Industrial Park Drive

Farmington Hills, MI 48335

Tel. 248-474-8200

Fax. 248-474-9518

Request a Quote